top of page

Engineered for high capacity, high performance

and outstanding value.

GRAIN STORAGE SYSTEMS

With MFS-Stormor grain storage bins you get the engineering, construction, flexibility and reliability that your business demands. All from a company that has specialized in grain storage and handling for decades.

In fact, MFS-Stormor bins are working in major markets all over the world, helping many of the world's largest, most successful companies improve their bottom line. How? By safeguarding grain quality, eliminating unnecessary costs and optimizing efficiency and value.

When it comes to grain storage on a commercial scale, no system does it better than a grain storage system with MFS-Stormor bins.

Why sacrifice strength and long life for price? With MFS/Stormor, you can have it all!

More than 50 years experience in grain storage systems

We’ve been in the grain storage business for decades. Commercial grain storage systems from MFS/Stormor are on the job on six continents, protecting the quality of huge volumes of grain in ports, processing and storage facilities of all sizes, types and designs.

A custom approach to every bin design

Every commercial bin we quote and build is designed for your specific installation, site and function. We’ll consider seismic conditions, frequency of loading and unloading, construction over a concrete hopper, types of material being handled, and other variables. We do our homework ahead of time so you get the system that makes sense for your operation and your budget.

The confidence to offer a 5-year warranty on commercial storage bins

We’ve made an unwavering commitment to outstanding innovation and engineering, high quality materials, and the latest in manufacturing technology. So we have absolute confidence in the ability of our commercial storage bins to perform over the years.

Industry-leading safety equipment & accessibility

From sturdy ladders and stairs to roomy access doors everything we do is focused on making your commercial grain storage system as safe and easy to use as possible. These built-in features can help you comply with OSHA guidelines.

Unmatched strength & integrity at a competitive price

Our commercial grain storage systems combine high-capacity storage, outstanding longevity and performance, and unique.

Commercial grain storage

systems from MFS/Stormor

are engineered to handle huge

volumes of grain efficiently—

while protecting the quality of

the grain and the safety of the

people working with it.

MFS/Stormor uses G-115(Z350)

hot-dip galvanization on key components of every commercial grain storage system.

Industry research indicates that G-115 galvanization can extend the life of the galvanized coating on the bin’s surface by up to 27% over competitors who settle for G-90 galvanization.

That means the galvanization on your bin maintains its integrity longer—and that means greater service life, increased reliability, optimal grain protection and a better return on your investment.

Design features with a very competitive price. Our wide range of options and ability to match our systems to your specific application enhance our ability to keep your system priced right without compromising quality.

Precise engineering for easier construction Bolt holes that line up. Sheets that are right sized, sized consistently and traceable. Sensible bundling of materials for easier handling on the job site. It all adds up to savings of time, labor and headaches.

Innovative design that solves big problems We’ve engineered features that address key issues such as personal safety, easier access, moisture resistance, structural integrity, stability and long-term performance.

ROOF SYSTEMS

Options to match your commercial bin requirements.

MFS/Stormor offers you a range of roof systems to match your commercial installation requirements and your budget.

72 ft. to 105 ft. Models (21.9 m to 32 m): Larger models typically need extra support due to larger capacity conveyers, catwalks and heavier spouts.

30 ft. to 60 ft. Models (9.1 m to 18.3 m): Option of raftered or non-raftered roof system.

Up to 30 ft. Models (Up to 9.1 m): Non-raftered roof systems are standard and generally meet or exceed roof load requirements for these sizes.

Every roof design has been tested for fit at the factory. All roof designs were initially assembled by our engineers before the first one shipped. This extra quality step means you don’t have to worry about dealing with a “prototype” during installation. Every bolt hole lines up. Every sheet matches. Rafters and purlins are precisely manufactured.

Engineered for long life and trouble-free construction:

G-115(Z350) galvanization on all outer roof sheets and most raftered components, leading to 27% longer life on areas

exposed to the elements. Components that require welding are not galvanized, but are powder coated for optimal protection.

30° roof slope helps void debris and snow from the roof system, without increasing overall bin height.

Temperature cable brackets are easily added to raftered roofs with minimal expense.

Powered roof exhausters are easily added with trouble-free installation on site.

Gooseneck vents with corresponding pre-formed vent opening allow for easier installation.

Three roof panels per sidewall sheet also simplify installation.

Proprietary state-of-the-art roll former controls the distance between holes from rib-to-rib, not from the edge of the coil like competitive products. The result: Higher quality roof sheets that fit better— with bolt holes that line up every time. Bolts drop

right in place. That means trouble-free, laborsaving, frustration-free installation on site.

“C” design on rafters and purlins dramatically improve roof integrity, especially when installed back to back. This design is ideal for the shape of the roof—and eliminates deflection commonly found in Z-shaped rafters. Rafters and purlins are manufactured by our sister company, Sentinel Building Systems—ensuring quality control, precision and timely production.

Extra-tall 3-3/4” (9.5 cm) stair-stepped ribs are staggered to provide even greater strength. Hemmed drip edge deflects moisture, eliminates sharp edges to reduce injury and strengthens the cross-section of the roof sheet.

Well-designed 2.25 sq. ft. (0.686 m2) roof vents for maximum airflow. Vent openings are pre-punched for easy

construction and tight fit and seals. Vents feature seamless raised lip (inset) for improved integrity and moisture resistance.

Extra-large manway is sized for plenty of shoulder-room and easy maneuverability, even for large-framed farmers wearing cold-weather gear!

SIDEWALLS

We’re 100% committed to 2.66" corrugation because we know it’s simply the best. Commercial grain storage systems are no place for compromise. That’s why we use 2.66" (6.76 cm) corrugation on every sidewall sheet every one. It’s best for hoop load, wind load and is performance proven over the years. This corrugation specification provides more steel per square inch when compared to wider corrugation of the same thickness and that matters when you have tons of grain inside the bin.

Optional side draw system is a common add-on to MFS/Stormor commercial grain storage systems. Available on most models, side draw installation provides high-speed, economical unloading. Side draw systems

include baffles and 12" (30.5 cm) outlet with rack and pinion gate.

Bolt-on base angle provides a strong finished edge to bin bottom and secure seal of bin to foundation when a sealer is added—providing greater integrity over competitors' pre-formed angles that are simply rolled into the sheet.

STIFFENERS

Structural integrity at every point.

Stiffeners provide integrity and optimal strength for the high eave heights typical of commercial grain storage bins. The stiffeners carry the vertical load, allowing the sidewall to account for hoop load. Choice of two or three stiffeners per sidewall panel provide optimal strength and stability depending on capacity and application. Stiffeners are easily mounted either externally or internally depending upon customer preference.

All stiffeners are G-115(Z350) galvanized to provide 27% longer life. Most stiffeners are ASTM A653 Grade 55 with 55K yield and 70K tensile strength.

Stiffeners are available from 8 gauge to 18 gauge to meet the demands of bins up to 105 ft. (32 m) diameter.

G115 galvanizing

of stiffeners provides up to 27% longer life. Most stiffeners are ASTM A653 Grade 55 with 55K yield and 70K tensile strength.

12 gauge splice ensures that stiffeners are properly butted to effectively transfer

vertical sidewall load to the foundation.

Heavy duty wind rings

are easily attached to the stiffeners on bins requiring this extra measure. Pre-punched wind ring holes and special attachments simplify installation.

“Hat shaped” stiffener design is proven through engineering studies to be the preferred shape for commercial bin stiffeners. This design carries the full vertical load to the foundation.

We design and build our commercial hopper bins to stand up to the constant use typical in a commercial grain storage operation. That goes double for the working parts of the hopper bottom where trucks go and grain flows on a daily basis.

Custom outlet heights available to accommodate installation of auxiliary equipment below the hopper.

Structure finish options include powder coated or galvanized to meet your specific application.

Heavy duty compression ring transfers load from the bin and hopper into the support structure. The base angle on the bottom of the tank is sealed to the compression ring for a weather-proof connection between tank and hopper.

Support columns are heavy I-beams engineered to carry the suspended weight of both tank and stored commodity.

COMMERCIAL BINS

BIN CAPACITIES

COMMERCIAL BINS

BIN CAPACITIES

COMMERCIAL BINS

BIN CAPACITIES

COMMERCIAL BINS

BIN CAPACITIES

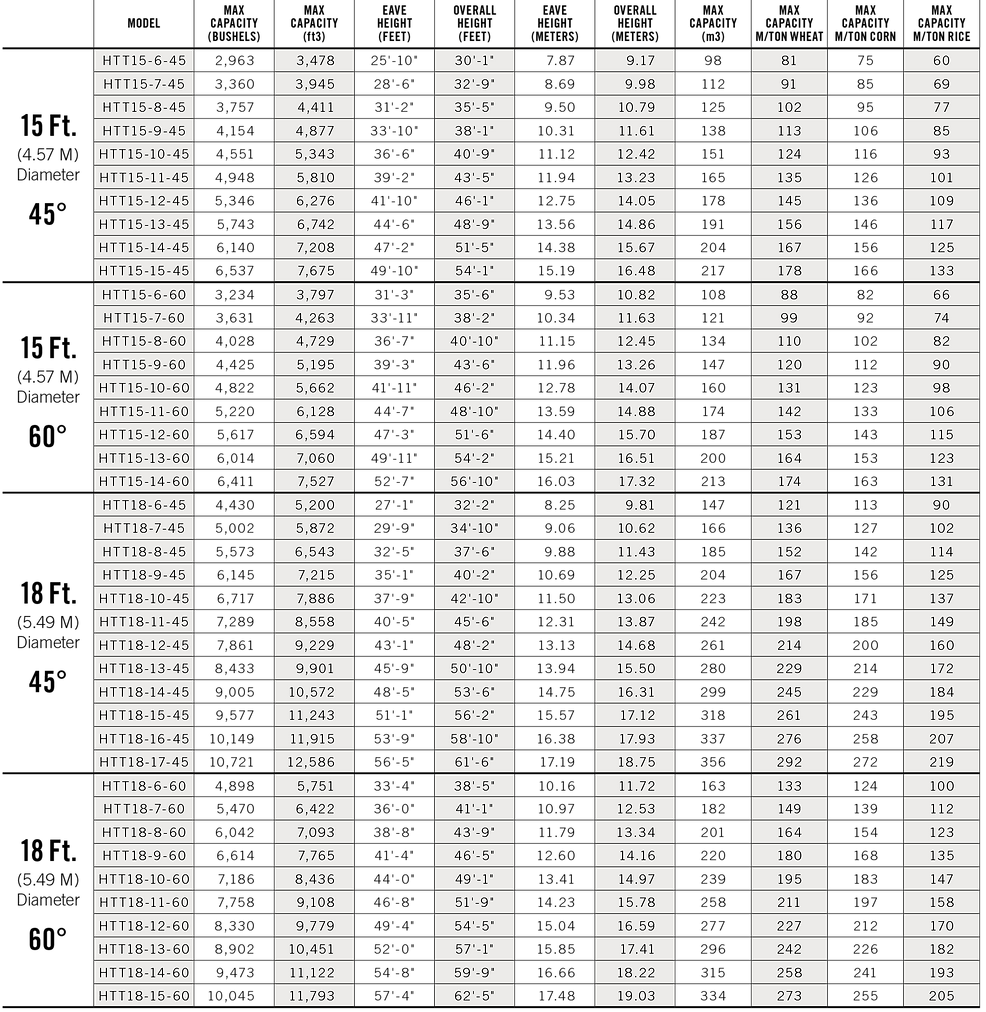

COMMERCIAL HOPPER BINS

BIN CAPACITIES

COMMERCIAL HOPPER BINS

BIN CAPACITIES

bottom of page